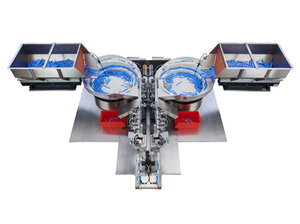

Industry solutions with the ROBO-POT system

Fastening technology

Feeding parts:

Concrete nails, nuts, rivets, bolts, union screws.

Requirements:

Usually wide variety. Rugged environments in use.

Solution:

Supplied by type and in correct position. Checked for special features (e.g. screws without heads, coatings). Transferred on accumulation track or clocked and provided individually.

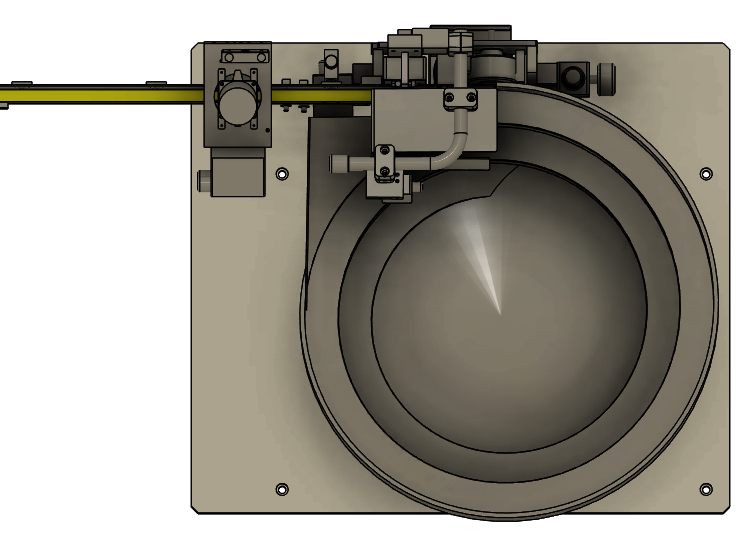

Defence equipment (ammunition)

Feeding parts:

Casings, cores, shell, cups, cartridges....

Requirements:

Wide variety. Robust environments in use. Sometimes tricky conveying behaviour of the parts.

Solution:

Supplied by type and in the correct position. Transferred on an accumulation route or timed and provided individually.