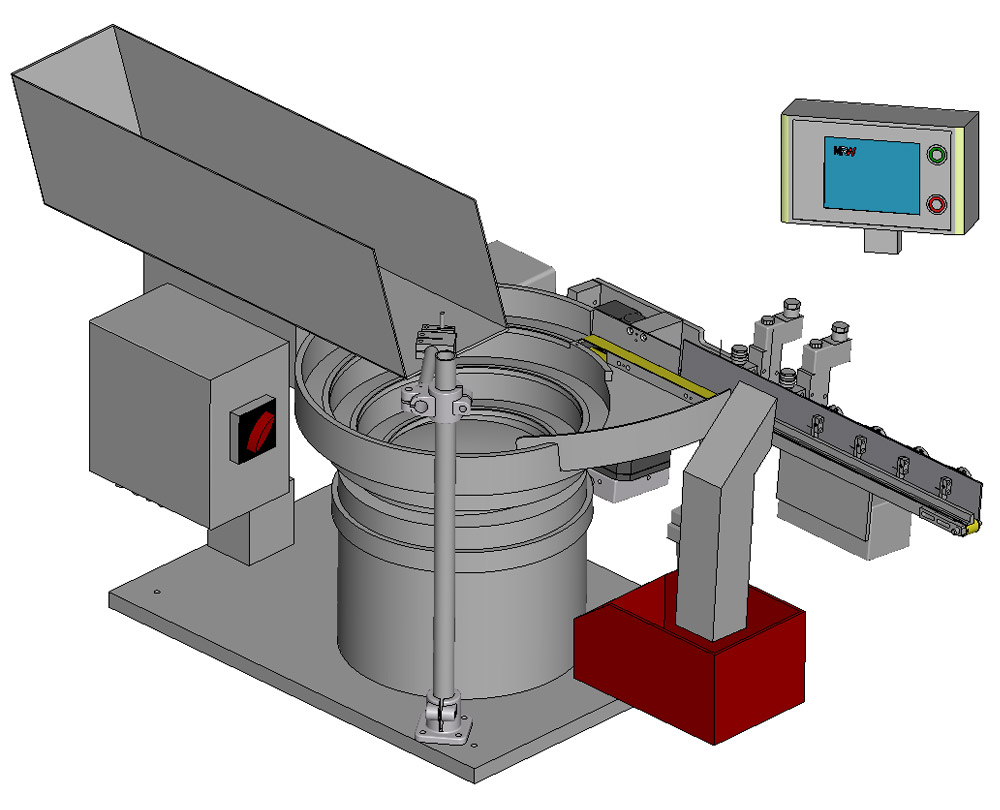

Parts stocking as a complete system

Our systems for the stocking of workpieces are individually developed and built to be gentle on parts, adapted to your production requirements. Equipped with digitally controlled level detection of the spiral conveyor bowl.

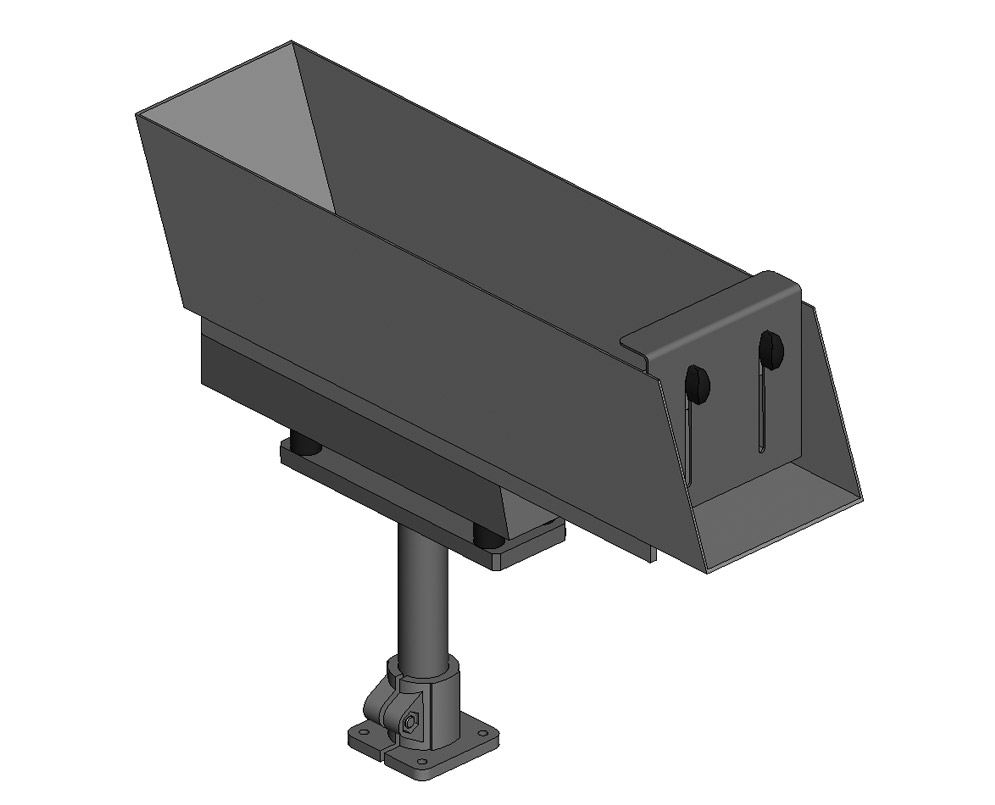

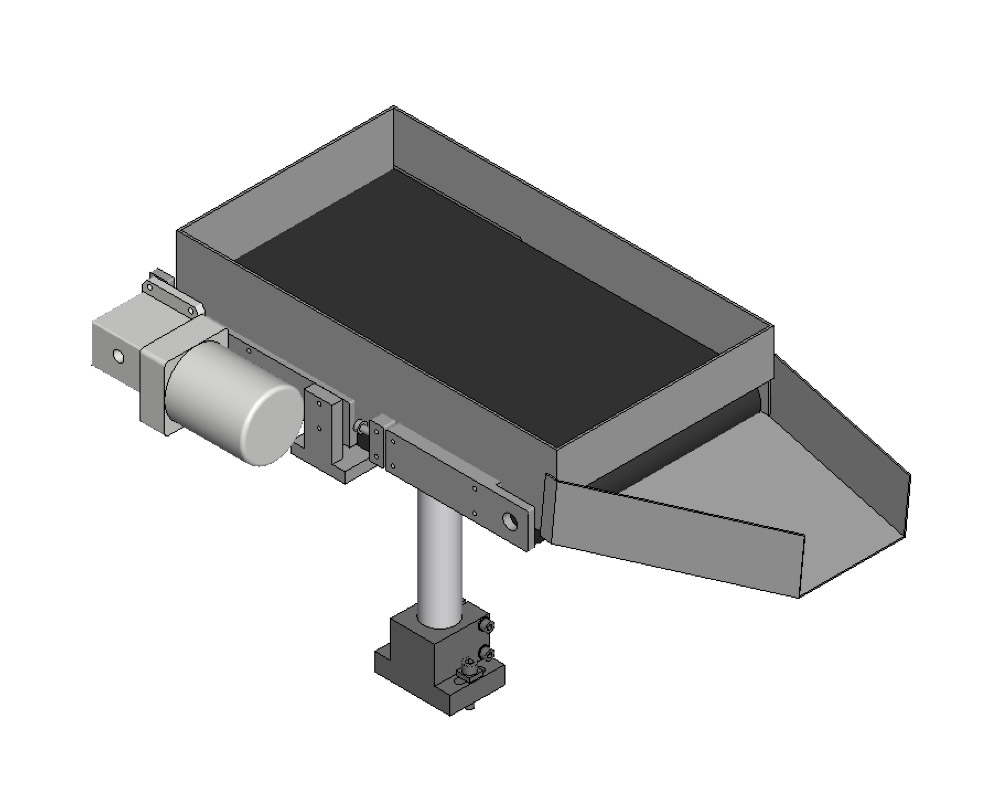

Standard vibratory hopper

| Construction method: | Horizontal, plain bottom |

| Volume: | 5 - 20 liters |

| Payload: | Up to 10 kg |

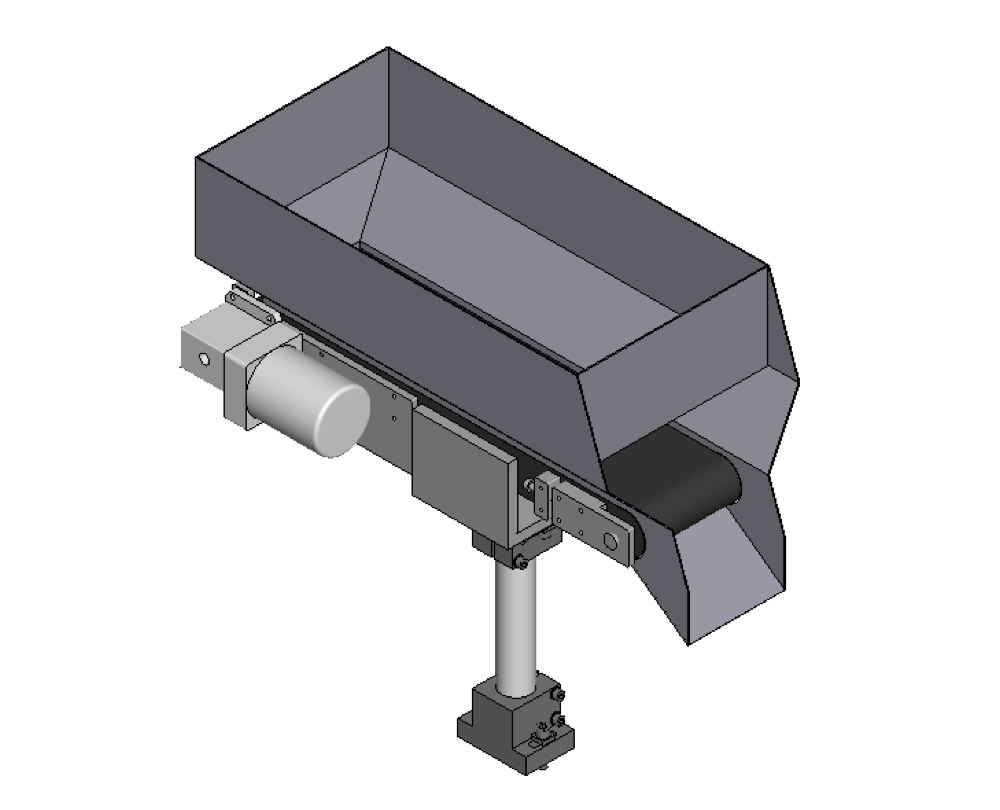

Standard belt driven hopper

| Construction method: | Horizontal, plain belt conveyor. |

| Volume: | 30 - 100 liters |

| Payload: | Up to 80 kg |

Inclined hopper

| Construction method: | Sloping, webbing with cleats or burls. |

| Volume: | 30 - 100 liters |

| Payload: | Up to 15 kg |

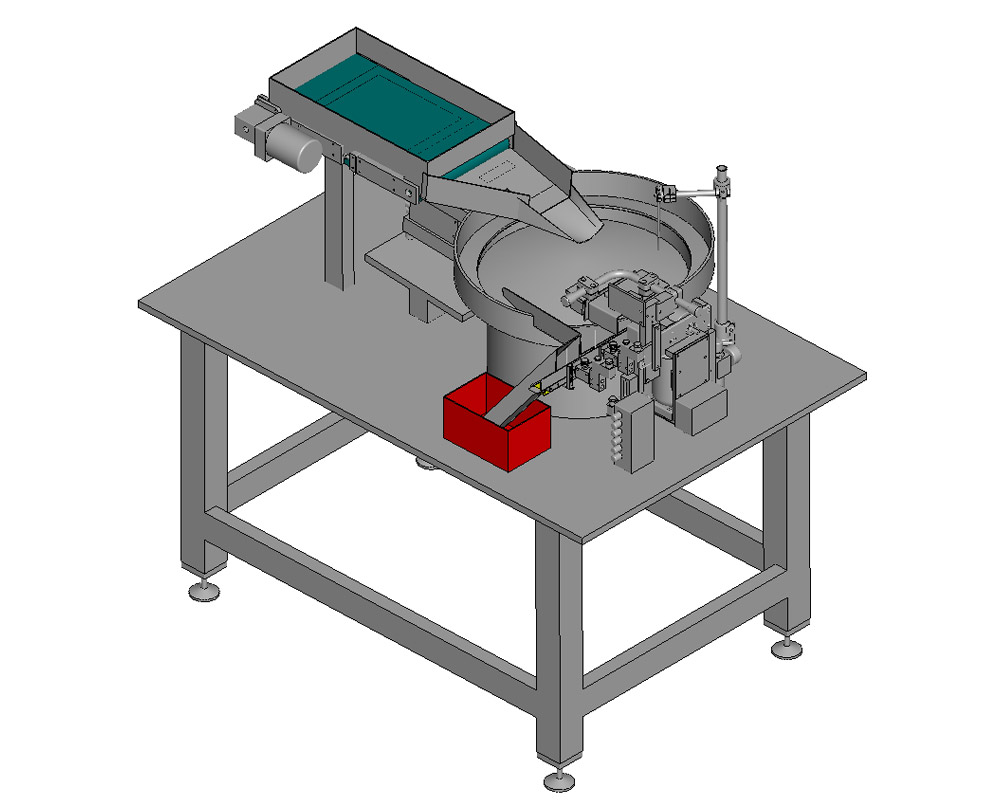

Area hopper

| Construction method: | Horizontal, flat, wide, plain webbing. |

| Volume: | Up to 20 liters |

| Payload: | Up to 80 kg |

Riser bunker

| Construction method: | Large trough. Horizontal top edge. Slope at the bottom. Riser conveyor with cleats |

| Volume: | Up to 200 liters |

| Payload: | Up to 15 kg |

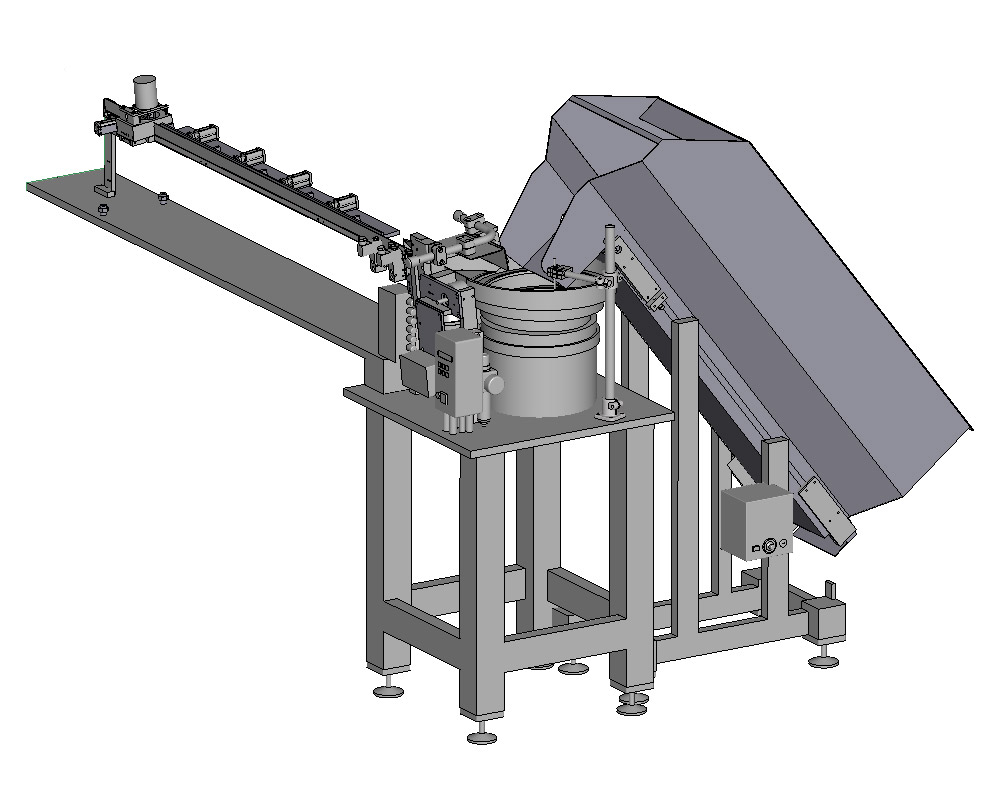

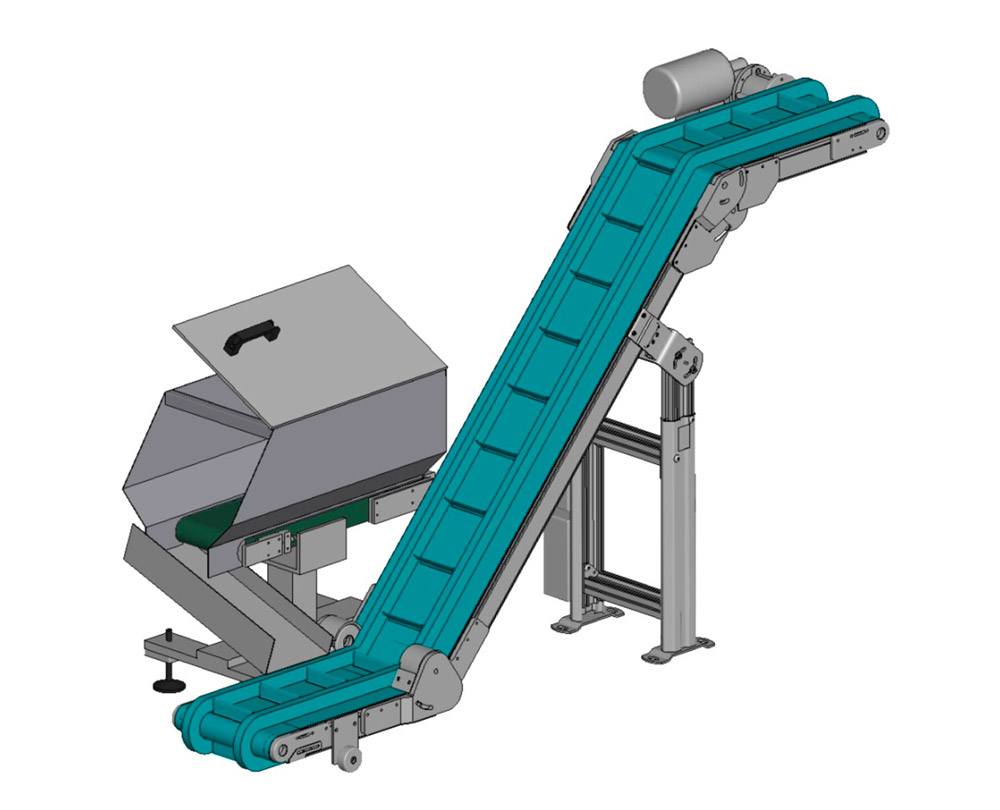

Ascending conveyor system

| Construction method: | Combination of horizontal hopper and separate ascending conveyor belt. |

| Volume: | Up to 100 liters |

| Payload: | Up to 80 kg |

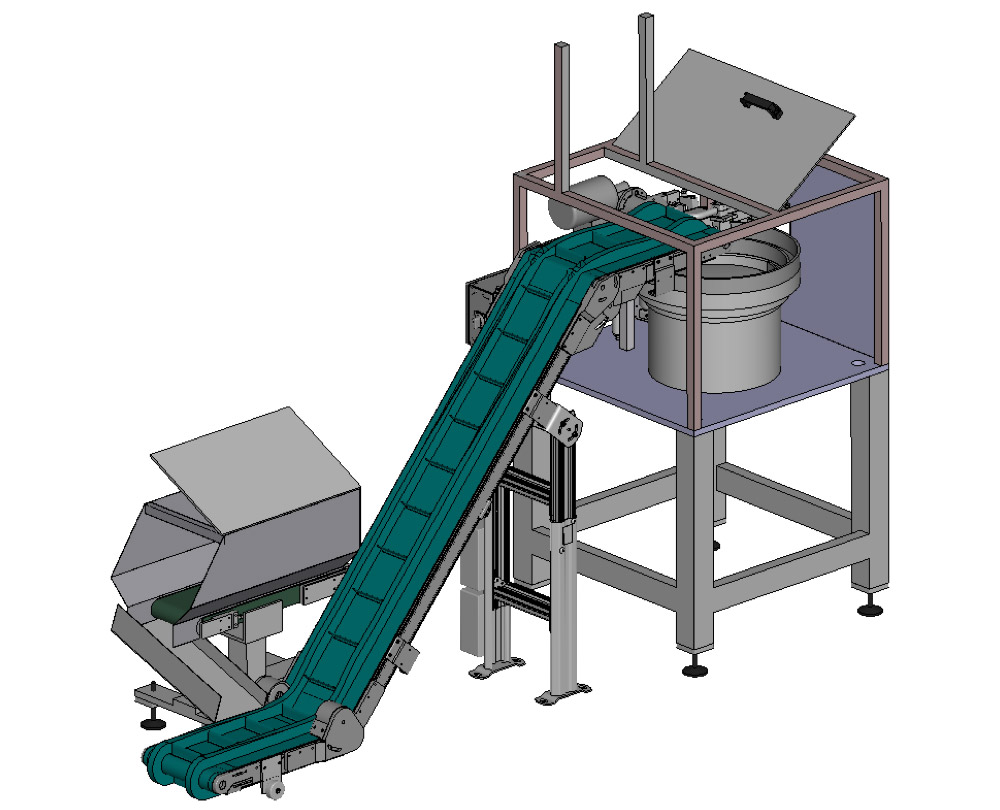

Ascending conveyor system with Z-belt

| Construction method: | Principle as for ascending conveyor system. Separate Z-belt with corrugated belt |

| Volume: | Up to 100 liters |

| Payload: | Up to 80 kg |

Facts:

Inclined hopper for ergonomic filling heights. Fixed or mobile with rollers and plug for quick disconnection.

Facts:

Area hopper for gentle stockpiling. Spread the weight of the workpieces over as large an area as possible.

Facts:

Combination of hopper and ascending conveyor. Very good ergonomics. Low filling height. Large discharge height. High filling weight.