Correct feeding based on the smallest features

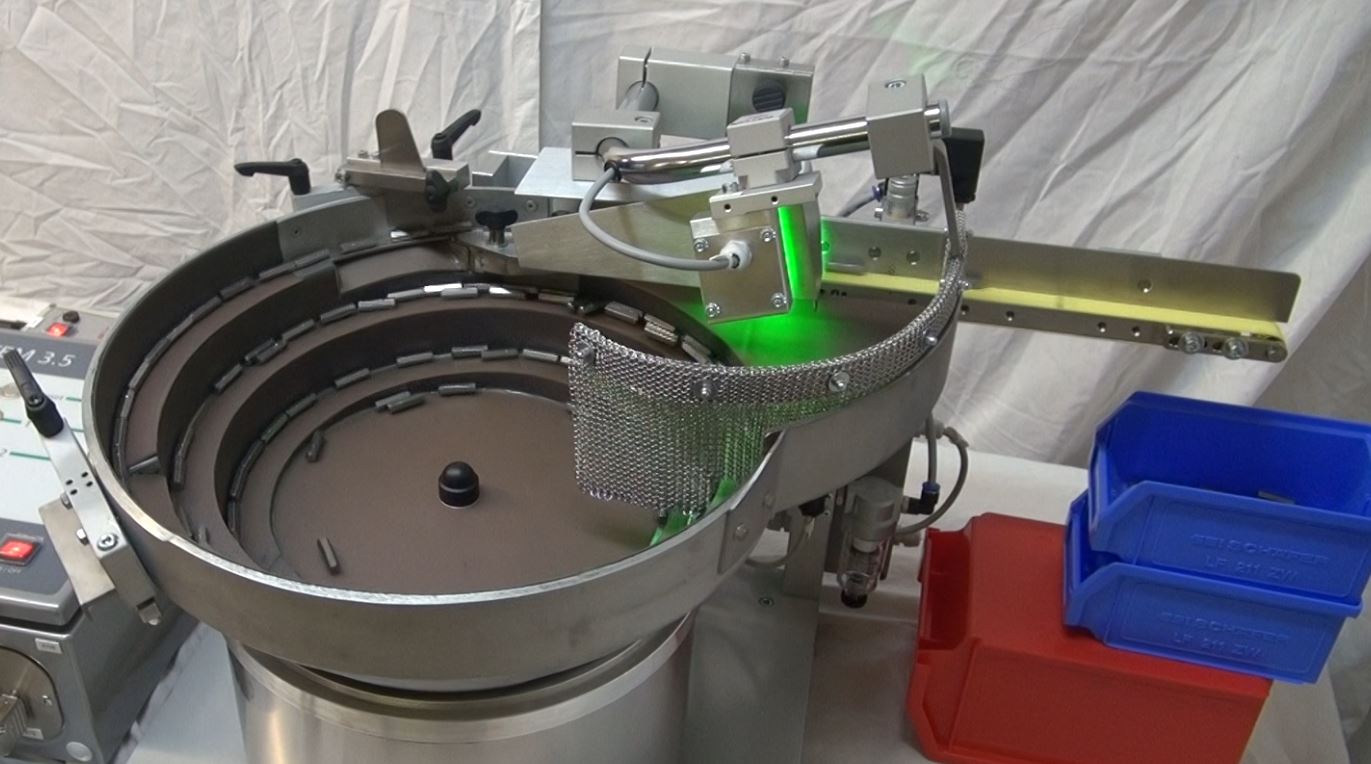

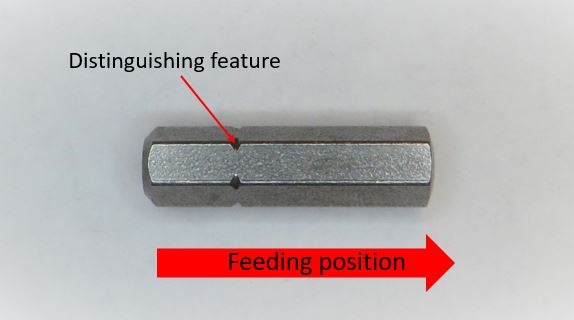

Feeding of screw bits in raw state

With the ROBO-POT 3.5 standard system including conveyor pot, a large number of part types can already be fed in the correct position without any problems. In the case of particularly small and difficult distinguishing features, special algorithms are used to highlight this feature.

Thus, as can be seen here, even the grooves of the bit can be recognized by the line camera and fed in the correct position at a speed of over 150 parts per minute.

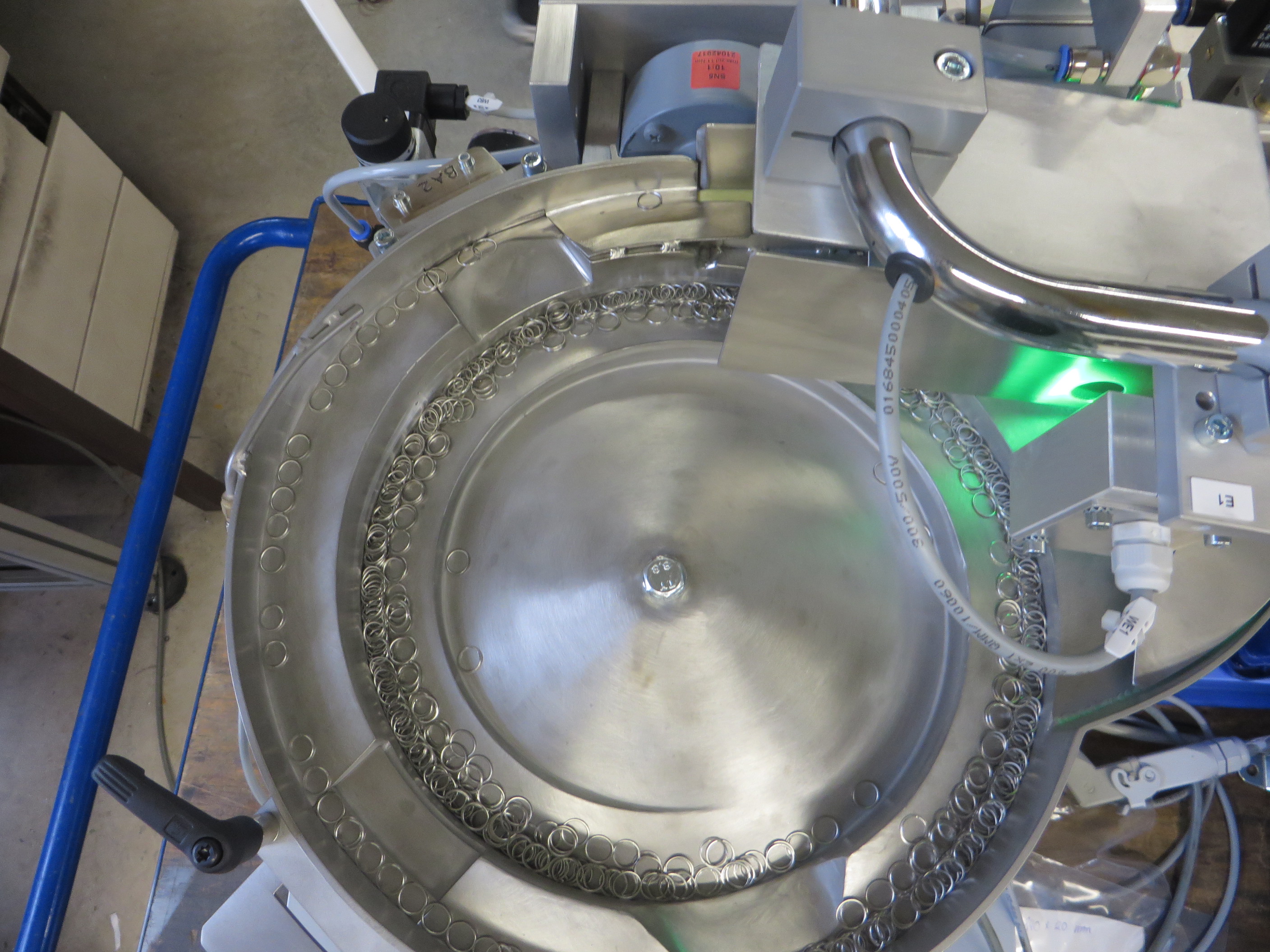

Flexible detection of sheet metal rings with inner contours

Detection of inner contours with 2D camera

The combination of angled back light, a gap between conveyor belt and slide rail, and special software make it possible to detect the orientation of rings with inner contours. This eliminates the need for another time-consuming and expensive image inspection from above.

In addition, the MRW system is able to feed ring diameters of up to 55mm. Adjustable rails and a simple program selection allow the usual MRW flexibility.

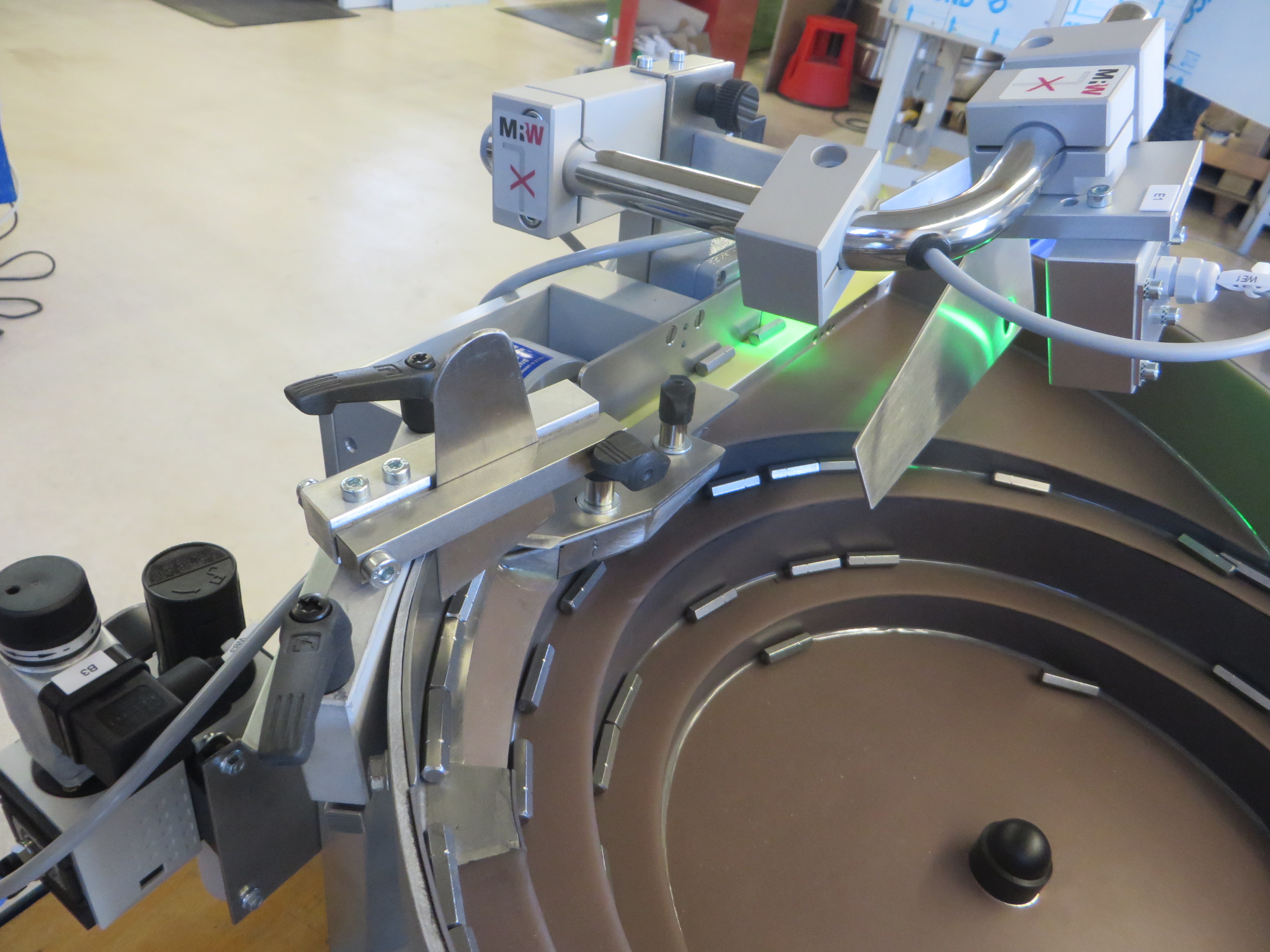

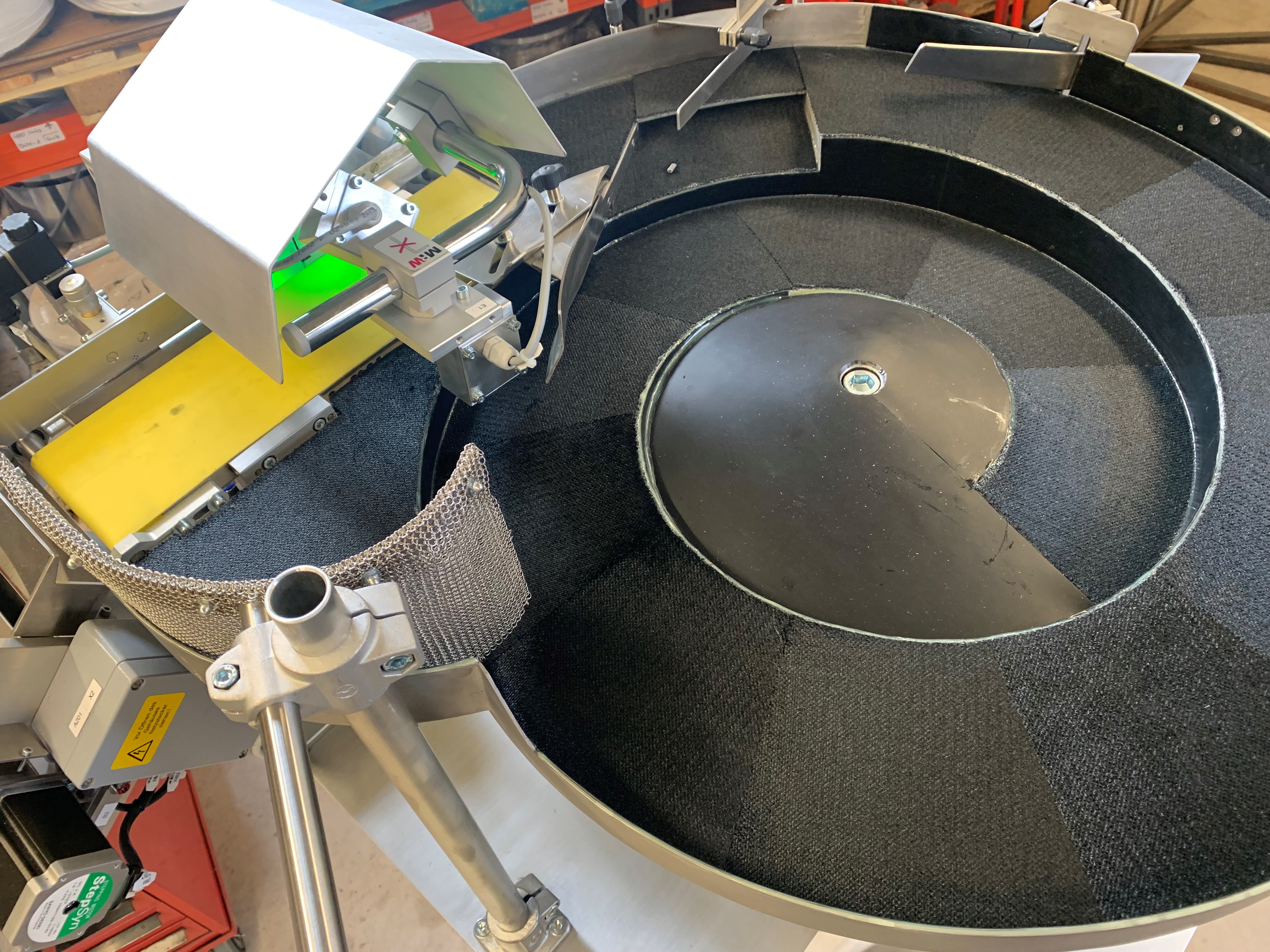

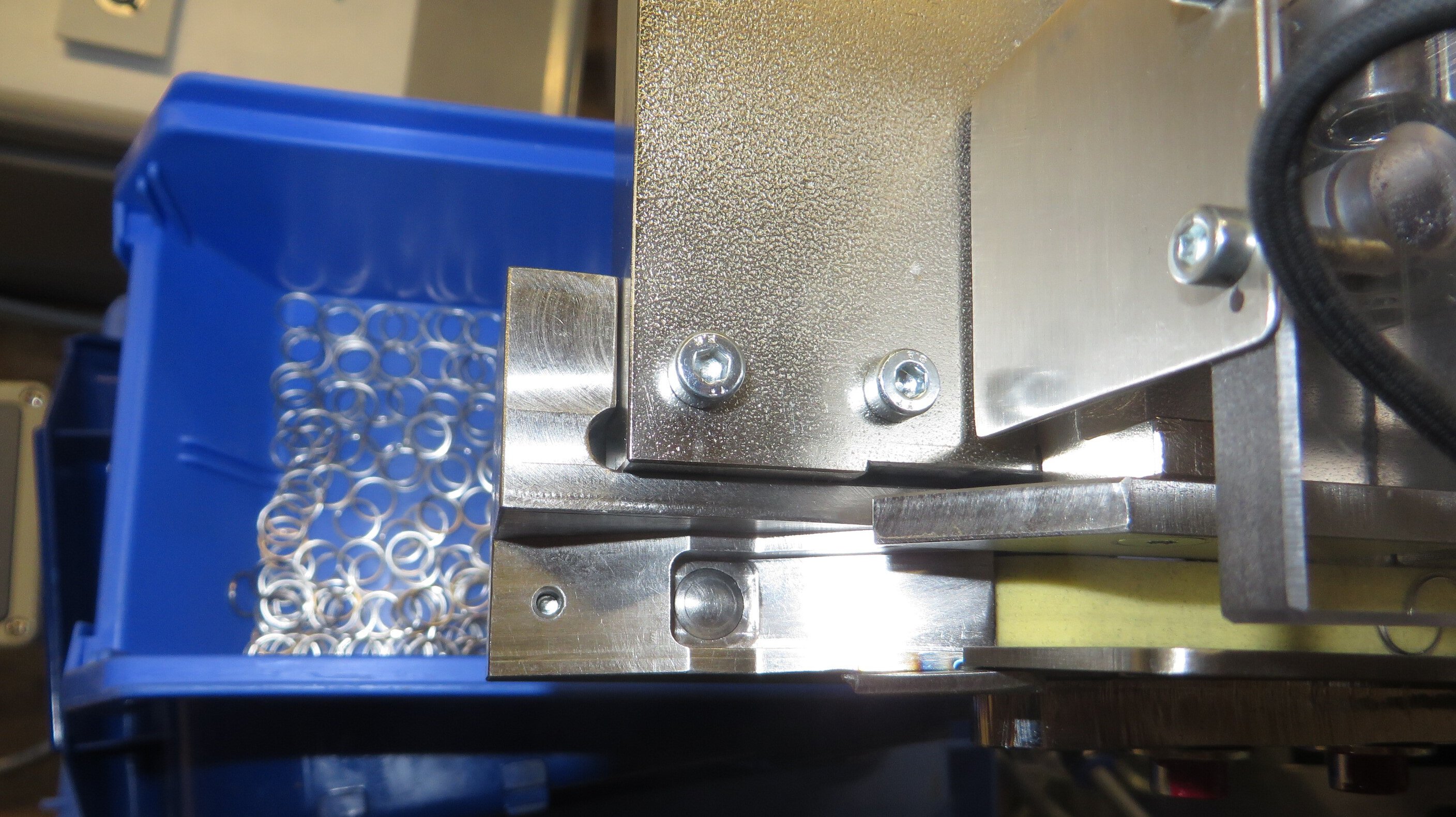

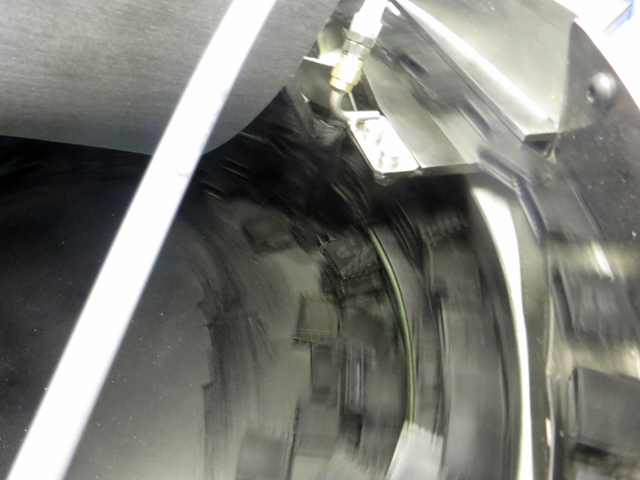

Application of a vertical turning station for rings

Correct feeding of rings with inner contours

The combination of an offset conveyor belt, angled lighting and a deep-seated MRW line scan camera makes it possible to detect the orientation of the rings based on their inner contours. Incorrect orientations are turned over by the vertical turning station. This is particularly suitable for flat and wide parts.

The MRW ROBO-POT offers great flexibility with a part spectrum of rings from 40mm to 120mm diameter completely without exchanging parts. The flat design of the pot with only one spiral leads to an excellent protection of the parts with a low drop height.

Perfect interface for gripper systems

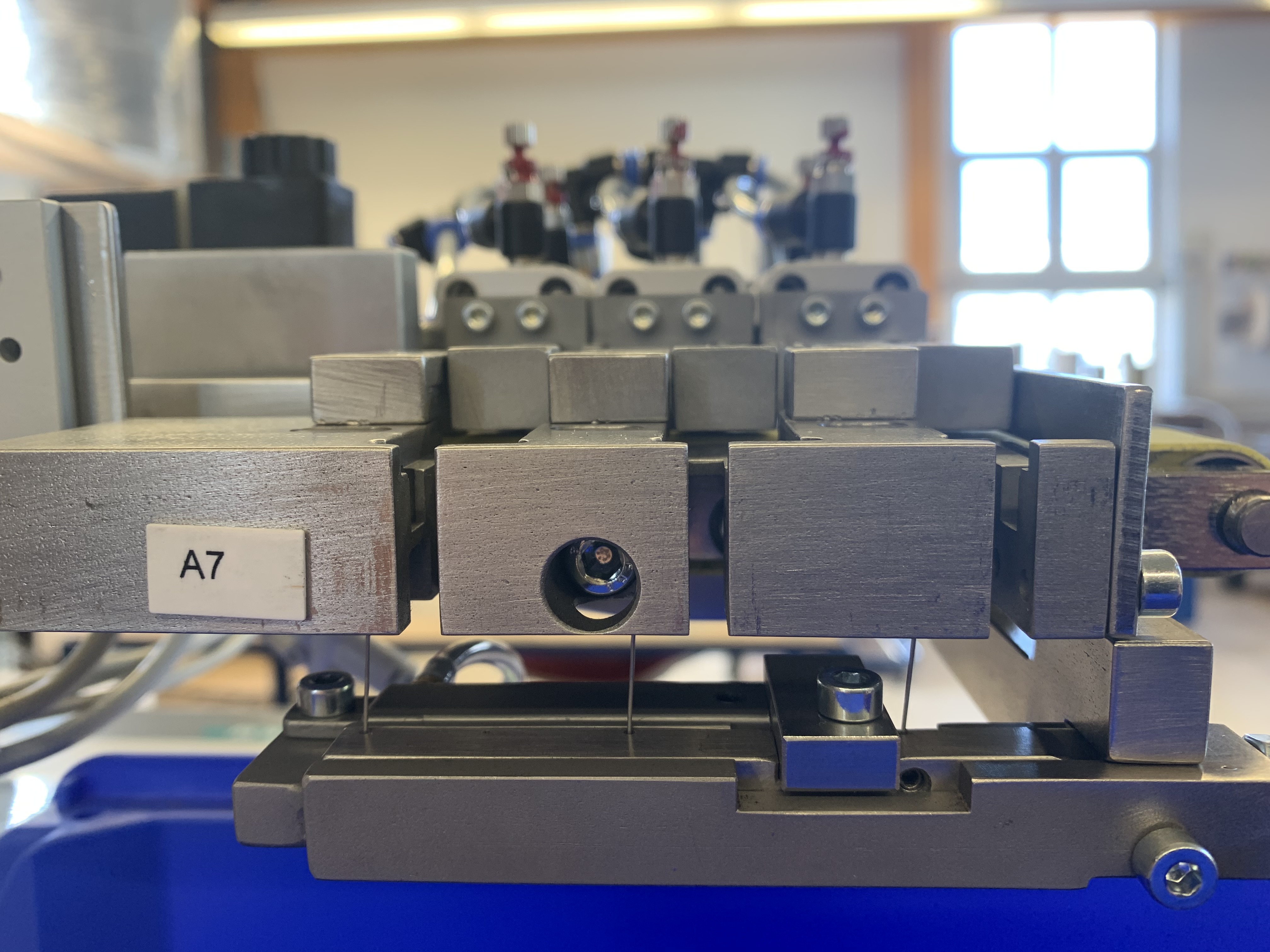

Separation and positioning of parts in the nest

With the providing of parts in the nest, the MRW ROBO-POT offers the perfect starting point for further automation. After exact positioning within the nest by using a longitudinal pusher, the parts can be easily picked out of the nest by a gripper. The ROBO-POT does not require any additional sensors and uses a time-distance control system to locate the parts.

A simple signal exchange between the ROBO-POT and further control systems, ensure a safe and efficient production process.

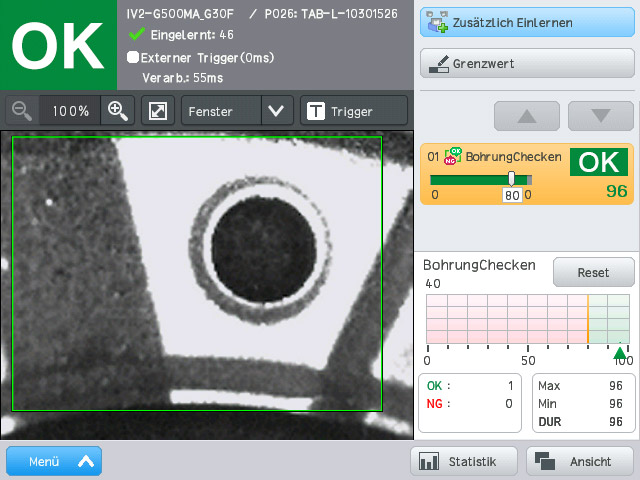

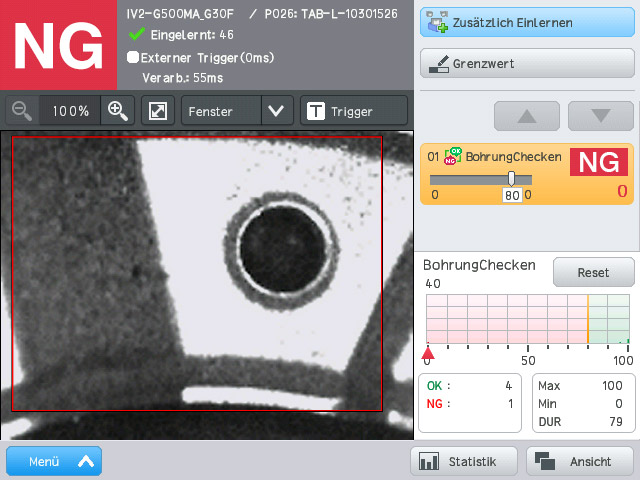

Image sensor Keyence IV2 autolearn successfully implemented.

Now more orientations per workpiece possible

With the innovative image sensor from Keyence, multiple orientations can be viewed per workpiece. This means a significant increase in sorting performance when a feature must be reliably detected in multiple workpiece orientations. The Keyence image sensor knows exactly which detail it has to check and which can be ignored.

Practical example: Often the contours of the workpiece are identical, only one hole makes the difference. Instead of previously using only one reference image, the contour and bore are now detected, checked and evaluated simultaneously with "Keyence IV2 Autolearn".

This sensor inspection recognizes defects in timely manner - for example before packaging - and thus avoids complaints due to incorrectly delivered parts.

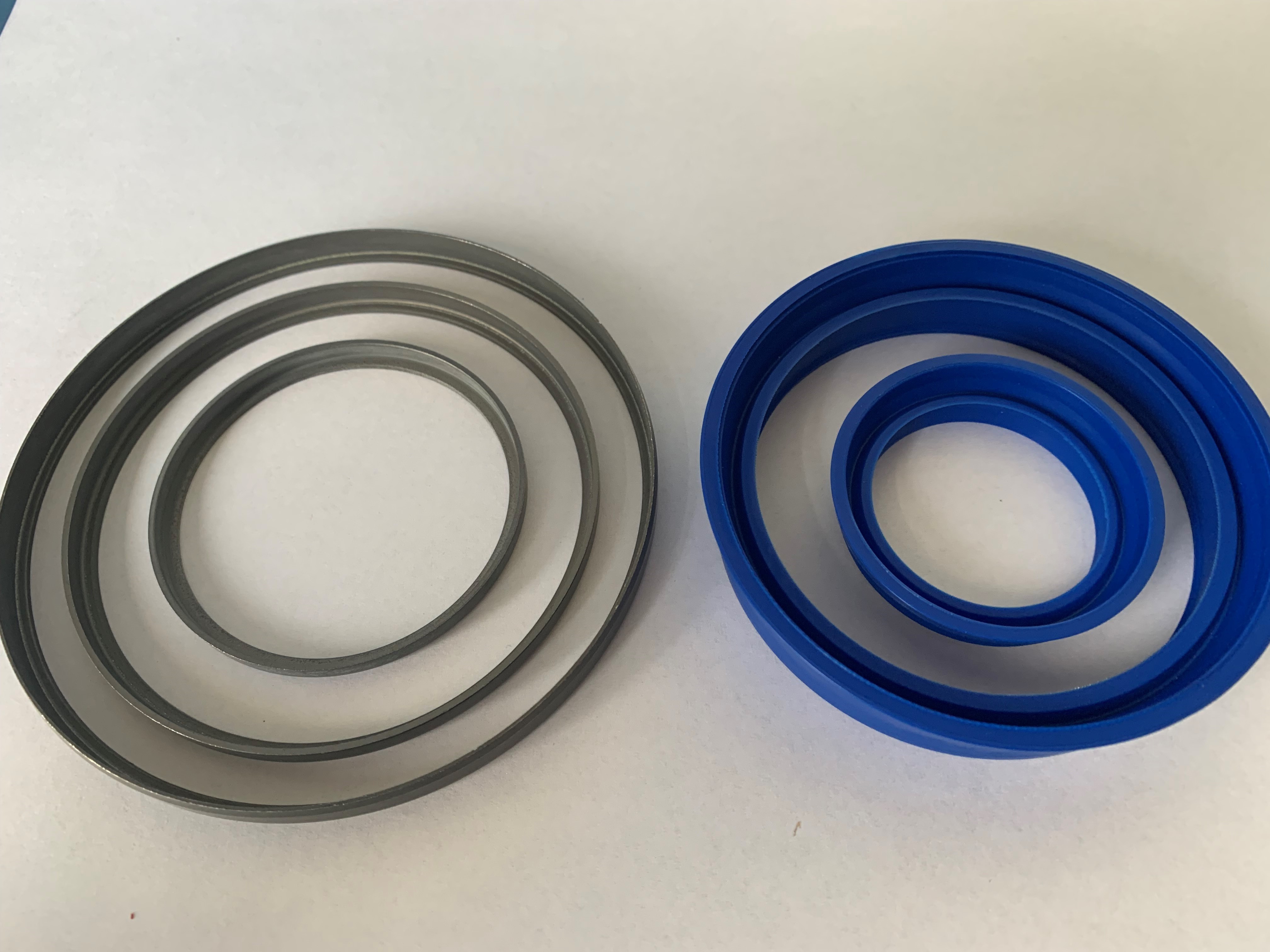

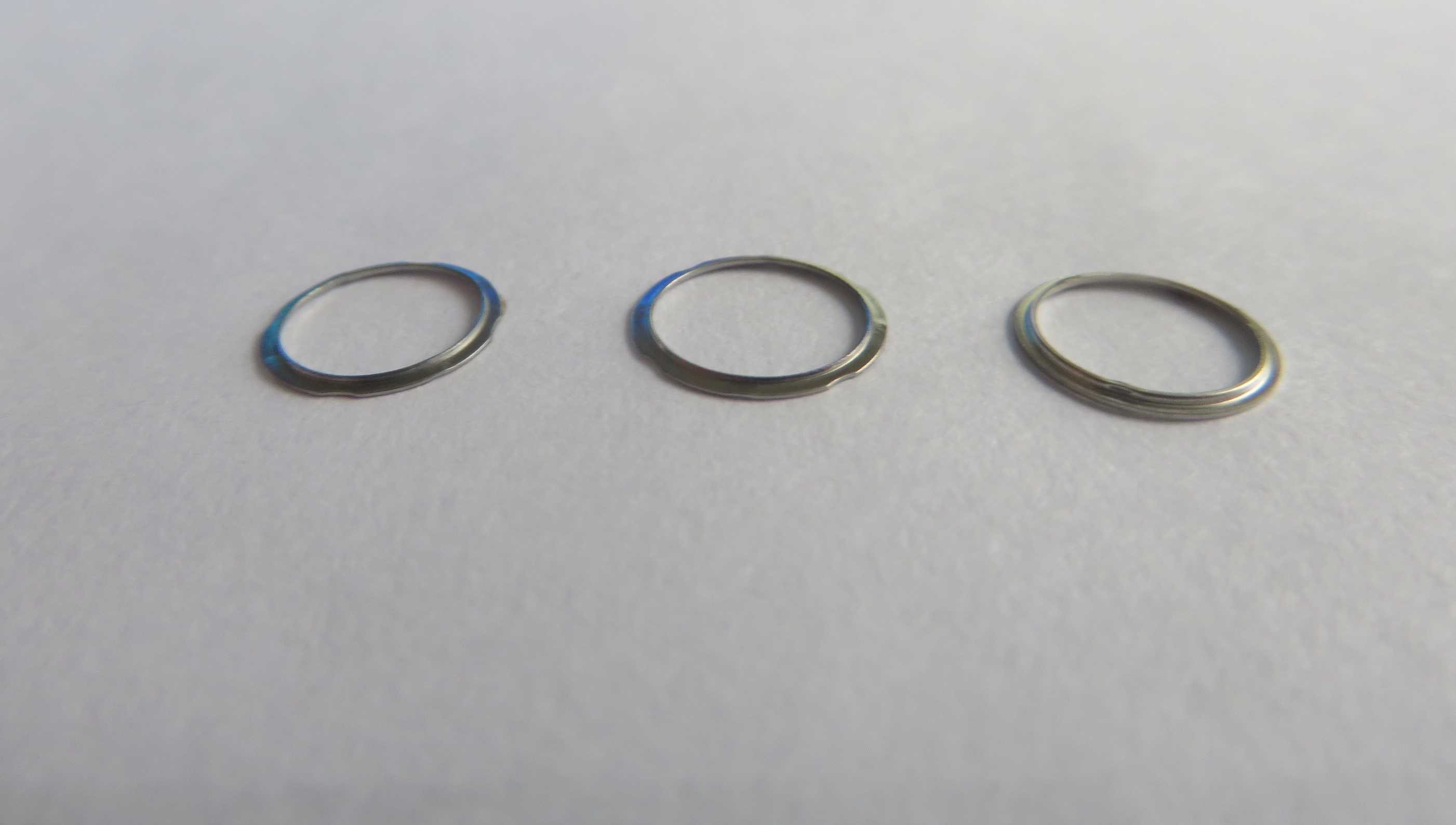

Accuracy of the line scan camera maximized

Sorting and feeding in correct position of sheet metal rings

In this system, the accuracy of the line scan camera has been fully utilized. Thus, the system is able to distinguish between the 3 different types by the diameter of the outer and inner ring only. These differ by only 0.3 millimeters. This prevents incorrect parts from being fed. Even the low height of the rings of 0.6 millimeters is no problem for the MRW line scan camera.

The 2 separating gates and the flexible nest guarantee simple and safe part handling.

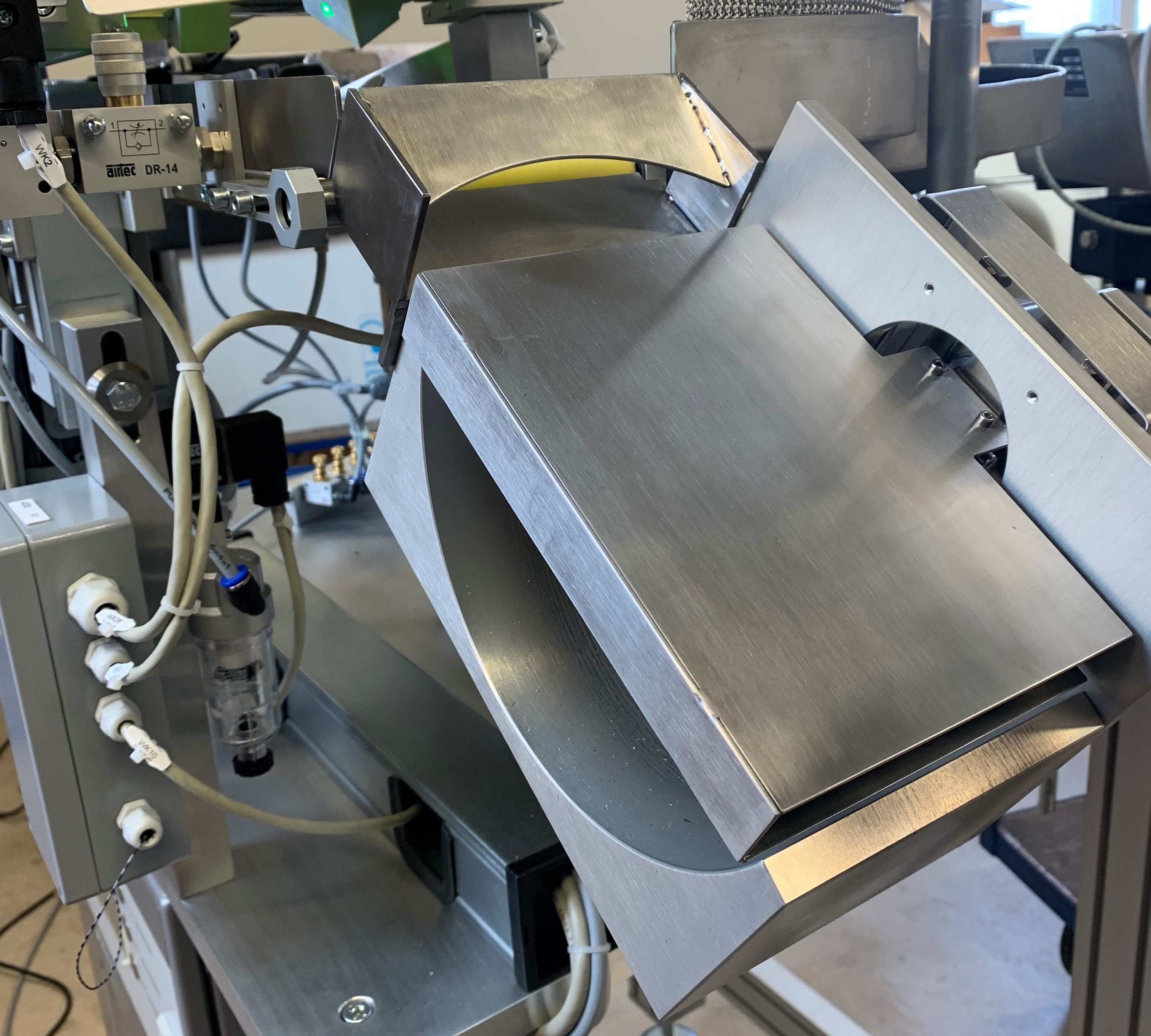

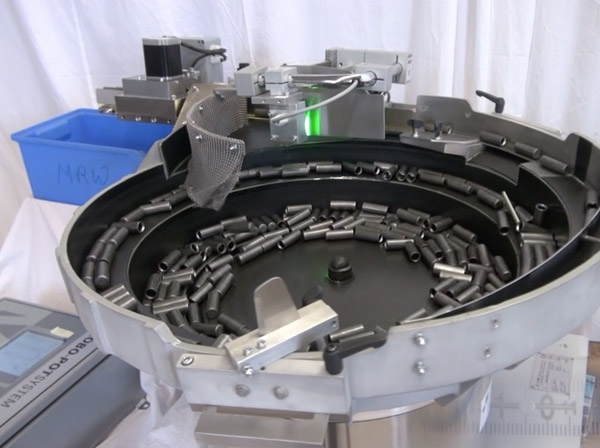

Perfect interaction of ROBO-POT and camera slide

Exact image inspection of rotationally symmetrical parts in the run

By pre-sorting and providing the parts with an adjustable minimum distance of the ROBO-POT, the parts have an optimal starting situation for the image inspection on the slide.

The high-speed image processing system with telecentric illumination and telecentric lens, in combination with the glass inserts, make it possible to detect deviations in the range of 0.01 mm. An intelligent control system sorts out bad parts with plausibility checks and controls the system combination of ROBO-POT, camera system and slide via an operating panel.

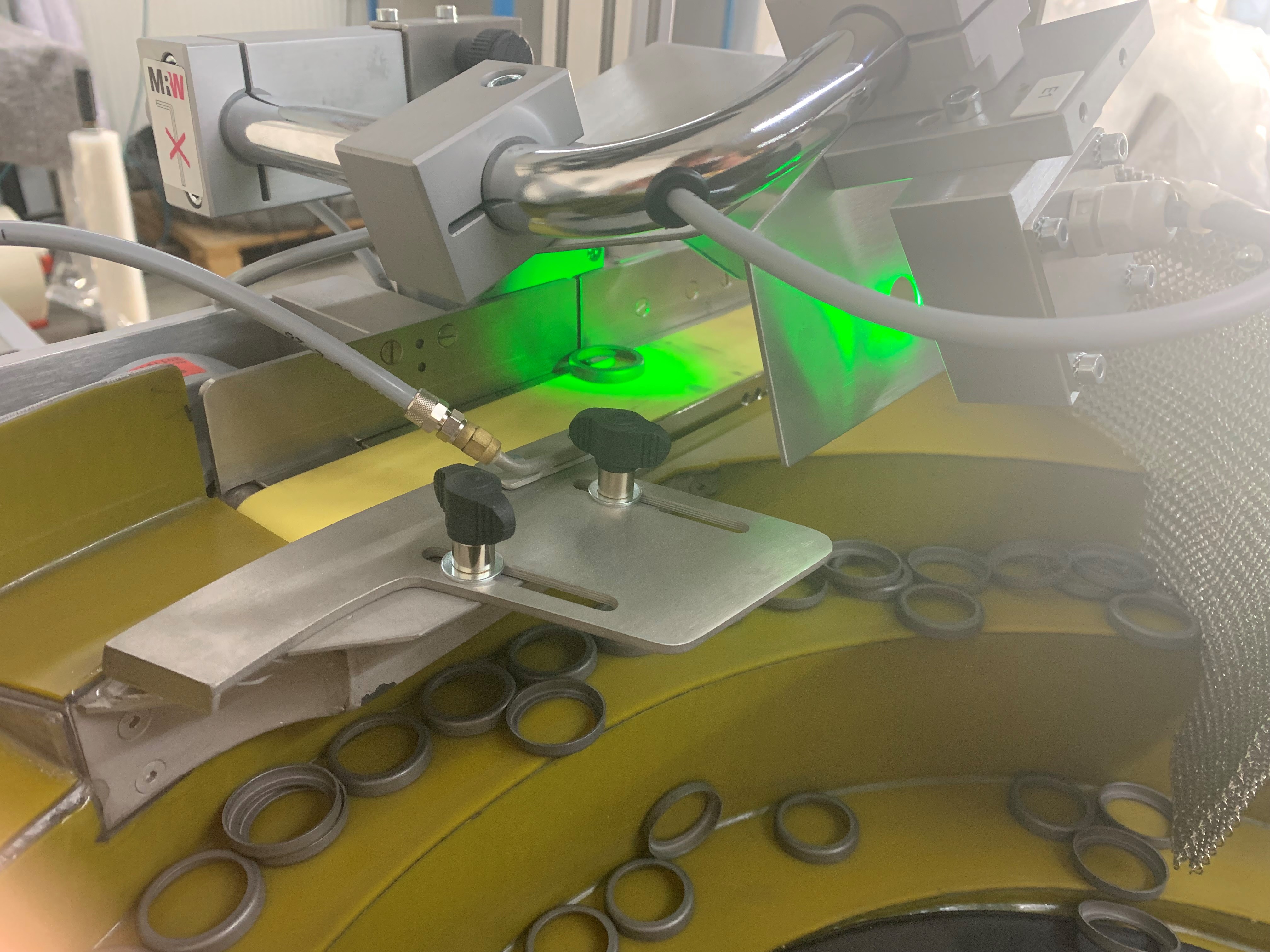

Flexible detection of sheet metal rings with inner contours

Detection of inner contours with 2D camera

The combination of angled back light, a gap between conveyor belt and slide rail, and special software make it possible to detect the orientation of rings with inner contours. This eliminates the need for another time-consuming and expensive image inspection from above.

In addition, the MRW system is able to feed ring diameters of up to 55mm. Adjustable rails and a simple program selection allow the usual MRW flexibility.

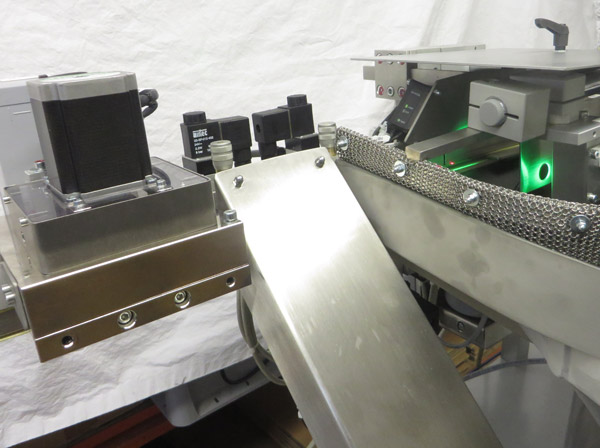

High-speed system for top performance

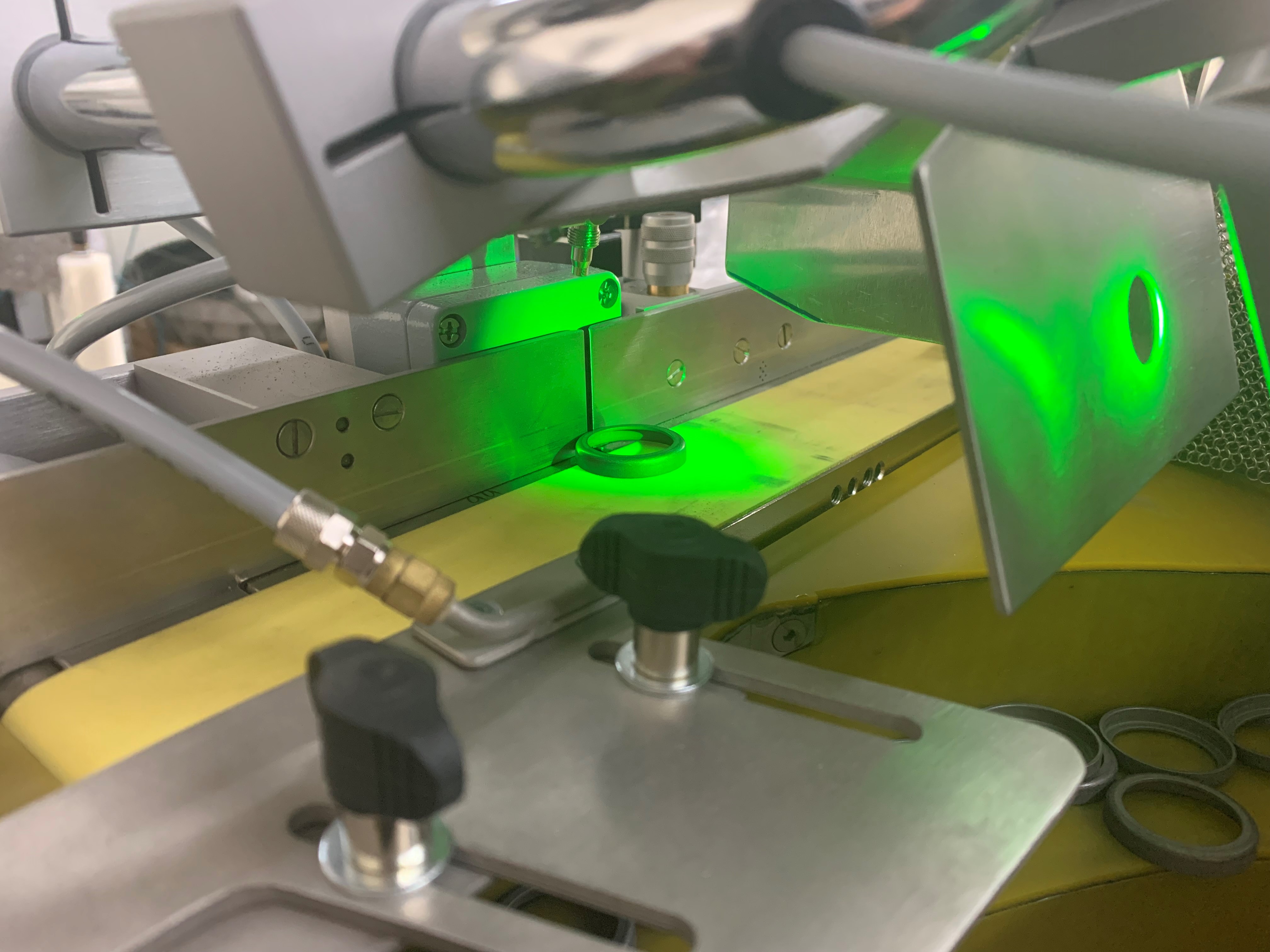

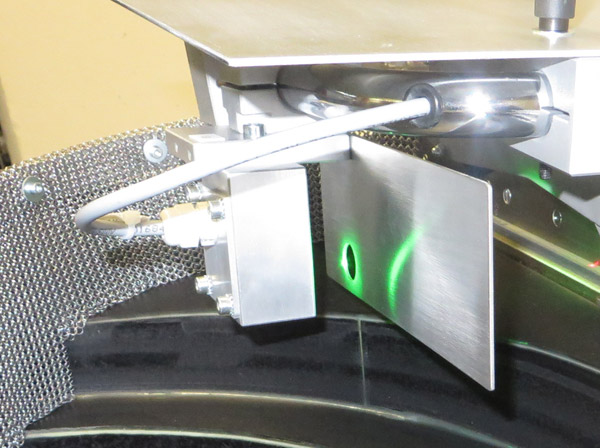

Turning station and laser technology optimally matched

The MRW system can perfectly inspect, sort and feed 100 to 200 bolts per minute, depending on length and characteristics, in tough, industrial 3-shift operation. The ROBO-POT system is designed for parts up to 120 mm in length with diameters up to 15 mm.

Crucial to this efficiency is the coordinated information processing of two Keyence lasers and the turning station by the ROBO-POT control system. The two distance lasers scan the symmetrical bolts on the front and rear sides, respectively, according to predefined characteristics. The turning station is then used to turn incorrectly oriented bolts in correct output orientation. Additional triggering is not necessary.

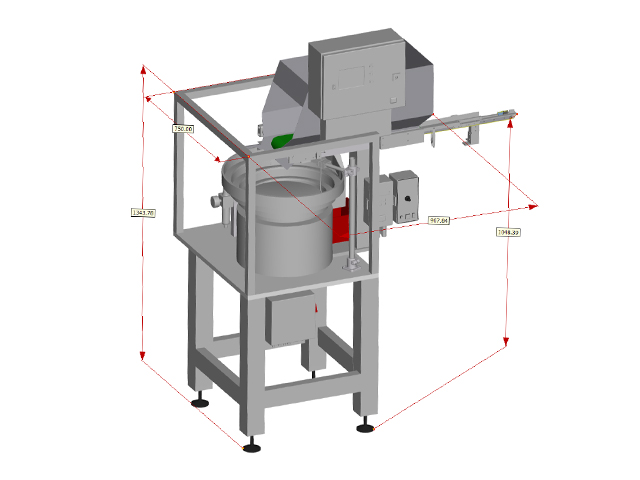

Maximum performance in the smallest space

for extremely limited space conditions.

The requirements of Eberhard AG - a machine building company in Schlierbach (BW) - were challenging regarding technology and available space in production.

With a lot of creativity and technological know-how beyond the normal limits, MRW developed an extremely compact ROBO-POT System 3.5, which contains all components for sorting and feeding SMD plug-in housings with lengths from 15 to 40 millimeters in the correct position. In quantities of 100 to 150 housings per minute.

MRW succeeded in a comparably short time to build the sound-proof ROBO-POT system in such a space-saving way that all necessary components could be integrated. The system with easily accessible controls includes: Spiral conveyor bowl, turning station, linescan camera for contour detection, laser for color detection, reject station and accumulating sections at the end of the belt. The video shows how unconventionally the individual components were arranged to solve the customer's complex task.

If new part types have to be fed, no retooling work is necessary. This means a further plus in efficiency under the limited conditions.